RxSugar keeps its supply chain sweet with Crisp

The RxSugar team keeps up with demand using real-time sales and inventory data.

Situation

Healthy demand, but limited supply

RxSugar CEO Steve Hanley is on a mission to end sugar. After discovering that sugar is added to 80% of all food and beverage products, he had an idea: if he could replace every gram of regular sugar with a healthy alternative, it would truly change the world. Steve found that alternative in the form of allulose, a natural, plant-based sweetener with 90% fewer calories and minimal glycemic impact. When the FDA officially distinguished allulose from regular sugar in 2019, he incorporated his new company, RxSugar, just days later. Fast forward two years, and RxSugar’s line of keto and paleo-friendly sugars and syrups are now available in over 12,000 stores, 30+ e-commerce retailers, QVC, and more.

Demand was high for the great-tasting sugar alternative, but the real challenge was to source the allulose, which is only produced by a small number of manufacturers. Addressing supply chain constraints required careful planning as RxSugar brought on new stores every day. Steve wanted to view aggregated insights across retail partners to inform his omnichannel strategy and production plan. He looked to bring all of his retail data under one roof, but struggled to get reports out of vendor portals from distributors and retailers. As Steve says, “I needed to go from a sea of information to information I could see.” That’s when he heard about Crisp.

Solution

Using data to deliver the goods

Steve remembers that Crisp “had him at hello”: the ability to automatically view aggregated data across distribution channels was exactly what he was looking for. Steve now opens up Crisp daily for insights to feed his business’ rapid expansion: “Every day I click on Crisp and all the information I need is there. It’s refreshed, it has a myriad of tools to drill into the data, and I can get an instant read into overall performance,” he says.

With updated top-line sales data, Steve’s team can accurately gauge demand to inform production and ordering of raw materials. As a result, RxSugar has gone from next-day ordering to 12 week lead times on materials and packaging. “We live in a supply constrained ecosystem, so the intimacy of insight provided by Crisp is vital to ensure that we are unwavering in our focus to optimize our omnichannel strategy. We’re now in a position to be able to forecast and be way ahead with our supply chain,” Steve explains. To help their omnichannel strategy succeed, Steve and his team check Crisp to monitor sales, distribution, inventory, and voids across retail locations. Steve sums it up: “Once you’re on Crisp, there’s no way you want to leave it. It’s lifeblood at this point for a business.”

Sweet results:

• Went from next-day ordering to 12 week lead times

• Saved time typically spent downloading distributor reports

• Managed distributions and voids across retail locations

• Supported a consistent omnichannel customer experience

Favorite Insights:

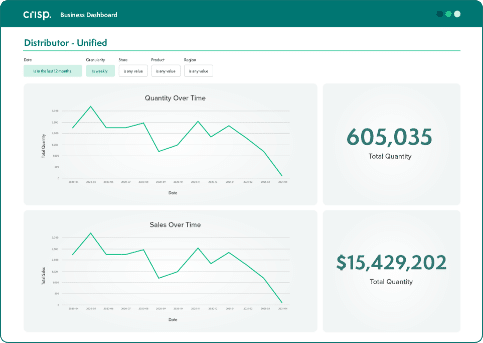

Unified Distributor Dashboard:

View aggregated sales data across distributors by geography, product, and banner.

Always be Data Ready with Crisp

Crisp allows food brands and retailers to stay ahead of rapidly evolving consumer behavior, identify potential supply chain disruptions, track inventory and product performance. It’s easy and quick to get started so you can be Data Ready.